When design and measurement are linked,

measurement operations change dramatically.

To increase the efficiency of measurement operations, take a close look at the design process.

Just adding tolerance information to 3D CAD models makes possible the "one-click"

generation of measurement models by "MiCAT Planner" CMM automatic measurement program generation software.

What took 45 to 60 minutes with a traditional "2D diagram" manual method and 15 to 20 minutes with a "2D diagram + 3D CAD" method, can now be completed in approximately 3 minutes using MiCAT Planner.

Using optimization functions, the smallest number of probe-position and tool changes and the shortest measurement path are determined by the software, and a program is generated for measurement in the minimum amount of time.

By shortening measurement time,

large measurement operation efficiency

gains are possible!

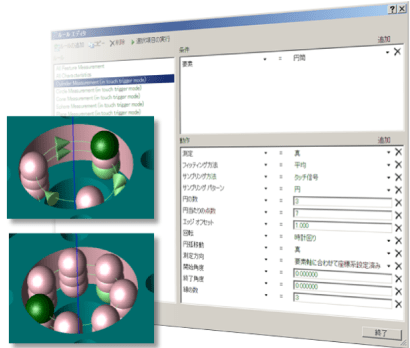

By defining measurement rules using the rules editor function, you can automatically generate a measurement path conforming to those rules. This prevents quality variations between programmers.

By defining measurement rules, you can automatically generate a measurement path conforming to those rules, so there are no variations between programmers.

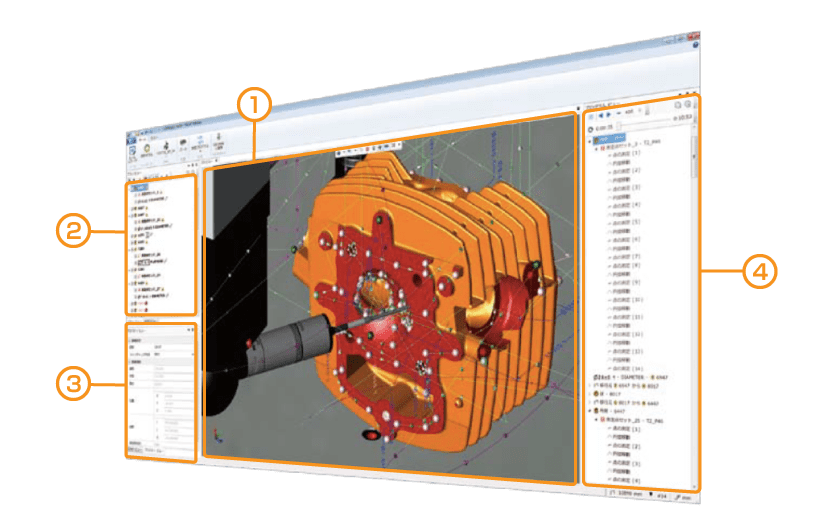

The MiCAT Planner screen configuration provides a "simple view" configuration that enables intuitive operations (3D view, plan view, etc.). You can also freely customize positioning and window size.

| ① 3D view | Graphical information is displayed. ・Measuring device information ・CAD models, tolerance information ・Measuring points, measurement path ・Measuring animation |

|---|---|

| ② Plan view | ・Display list of measuring elements, tolerances, etc. ・The existence of measurement and evaluation can be selected using a check box. |

| ③ Property view | Element, tolerance, and measuring point name changes and measuring point editing can be done for each individual element. |

| ④ Program view | ・Display measurement details and projected measurement times. ・Using the animation function, it is possible to execute a 3D-view measurement animation. |

| CAD formats | Extension |

|---|---|

| ACIS | .sat |

| STEP | .step/ .stp |

| NX | .prt |

| Creo Parametric (Pro/E) | .prt/ .prt. |

| CATIA v5 | .CATPART |

| Solid Works | .sldprt |

【15 languages supported】

Japanese, English (US/UK), German, French, Spanish, Portuguese, Italian, Chinese (simplified/traditional), Korean, Polish, Czech, Dutch, Turkish, Russian