- Home

- Technology

- Applied Technologies for Products

- Technical Information

1. Introduction

With the recent brisk pace of progress in the machining accuracy of machine tools, workpieces are being measured with unprecedented high accuracy. To meet the needs of measuring instrument users, the accuracy level has been shifting from the μm scale to sub micro-meter and even nano-meter scales.

In response to these trends, MITUTOYO has developed and marketed its LEGEX Series of ultra high accuracy coordinate measuring machines as part of the next-generation of CMMs.

The basic technologies behind the development of LEGEX are described below, along with LEGEX Series specifications and performance features.

2. How Ultra High Accuracy Was Achieved

2-1 Basic Structure

To ensure accuracy, fixed and movable table types are used to minimize Abbe's offset error.

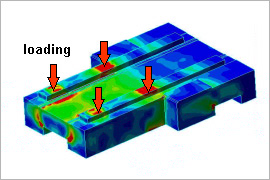

In fact, FEM analysis was used to help design the optimum structure for these products.

2-2 Measurement Technologies

These measurement systems that use three reference axes include a newly developed linear encoder system featuring a crystallized-glass scale with a resolution of 0.01 mm and an ultra-low linear expansion coefficient of 0.01 x 10-6/oC. With thermal expansion of nearly zero, these systems achieve ultra high accuracy with improved thermal stability. Figure 2 illustrates the detection system used in these products.

Figure 1. FEM Analysis of Base (Example) |

|

Figure 2. Detection System |

|

2-3 Drive Mechanism The center of gravity drive system places the drive units near each carriage's center of gravity for each slide, and thereby improves dynamic accuracy by reducing the moment of inertia during acceleration and deceleration. 2-4 Vibration Control Techniques • Internal vibration MITUTOYO uses its proprietary highly rigid low-vibration air bearings to achieve high accuracy and stable guide operation by damping vibration from two main sources of internal vibration: spindle motors and guide rails. • External vibration To keep the installation site's floor vibrations from adversely affecting precision, MITUTOYO has placed air-damped spring isolators equipped with an auto-leveling function at the center of gravity position in the base. This technique effectively eliminates external vibration to ensure stable accuracy. 2-5 Probe Technologies The MTP2000 is a touch trigger probe developed for ultra high accuracy measurements. The MPP300 probe enables high precision scanning measurements as well as high precision point measurements. |

|

|

3. LEGEX Series Specifications

3-1 LEGEX Series External View and Specifications

Figure 5 shows an external view of the LEGEX12128 from the LEGEX Series, and Table 1 lists the Series' specifications.

|

Figure 5. LEGEX12128

|

Table 1. lists the Series' specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4. LEGEX Performance Evaluation

Results of inspections based on CMM inspection standards (ISO10360-2) are shown for the LEGEX12128 in Figure 6 and for the LEGEX9106 in Figure 7.

The red lines in these figures are rated values for accuracy, taken from measurements repeated five times each at measuring points from 30 mm to 1000 mm.

Figure 6. Error of Indication Measurement Results for LEGEX12128 |

|

Figure 7. Error of Indication Measurement Results for LEGEX9106 |

5. Conclusion

We have briefly examined just some of the specifications and elemental technologies for the LEGEX Series of ultra high accuracy coordinate measuring machines. For the future, MITUTOYO plans to further advance its technologies and develop new Series products with an even greater array of performance features and functions.

|

Published in "Mechanical Engineer (Japanese only)" by THE NIKKAN KOGYO SHIMBUN, LTD. July, 2004. |