1. Preface

Mitutoyo promptly started manufacturing and selling a vision measuring machine that measures images by capturing with image sensors such as CCD through optical lenses to implement non-contact measurement of dimensions of geometrical features and their positions. Since measurement of complex forms or forms having a high aspect ratio are to be implemented simultaneously due to the fine processing techniques enhanced in recent years, we released Hyper Quick Vision WLI, which is equipped with a white-light interferometer (WLI). ISO and JIS are accelerating standardization of three-dimensional roughness (ISO 25178-6:2010) and are establishing terms, definitions and surface texture parameters for geometrical product specifications (GPS) of JIS B0681-2:2018 products in Japan in recent years. For three-dimensional roughness, since it takes time to measure using a conventional stylus roughness measuring instrument, Electro-Magnetic Surface, which detects surfaces by electromagnetic wave as a method introducing three-dimensional roughness, is defined in ISO and JIS. (JIS B0681-6:2014) In fact, requests for three-dimensional measurement with the non-contact detection principle for spatial parameters and tribology analysis such as WLI are increasing.

We introduce the specifications of QV WLI equipped with a white-light interferometer and applications here while explaining about ISO and JIS movement for non-contact three-dimensional roughness in this chapter.

2. QV WLI Specifications

(1)WLI principle

Split the white light projected from a light source into two light fluxes toward the reference mirror and toward the measurement sample using the beam splitter inside the interference objective lens. When the interference objective lens is scanned in the Z-axis direction, white interference fringes are generated only on the area where the test sample is being focused on.

A 3D form of the workpiece is obtained by detecting the intensity peak position of these interference fringes at each pixel position of the CCD.

|

|

Fig. 1

Schematic drawing of WLI optical system

|

Since the z-axis resolution does not depend on the lens magnification of the objective lens, this detection principle increases measurement efficiency by widening the visual field while maintaining the z-axis resolution.

(2)QV WLI specifications

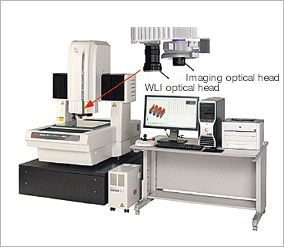

In the QV WLI series, seamless automation of vision measurement and non-contact three-dimensional form measurement is enabled by arranging the optical head for vision measurement and WLI head in parallel.

|

|

Table 1

Specifications of QV WLI |

(3)QV WLI measurement case example

Fig.2

Appearance of QV WLI (Hyper QV WLI 404)

|

Although it was difficult to obtain a three-dimensional form with high aspect ratio using the conventional optical system for vision measurement, the WLI head equipped on QV WLI enables obtaining a high aspect ratio three-dimensional form with high resolution and at high speed.

|

|

Fig.3

Measurement example of fine wiring width of semiconductor package |

|

|

Fig.4

Dimension analysis example from three dimensional form |