“はかる”がつなぐ、

ものづくりの未来

2024年10月22日、

ミツトヨは創業90周年を迎えます。

ミツトヨは、業界で最も多い5,500種類以上の商品を取り扱う世界有数の精密測定機器の総合メーカーです。「測る」を通じて、ものづくりに携わるお客様や社会の持続的発展と価値創造に貢献します。

ミツトヨはJCSS校正認定事業者です。詳しくはこちら

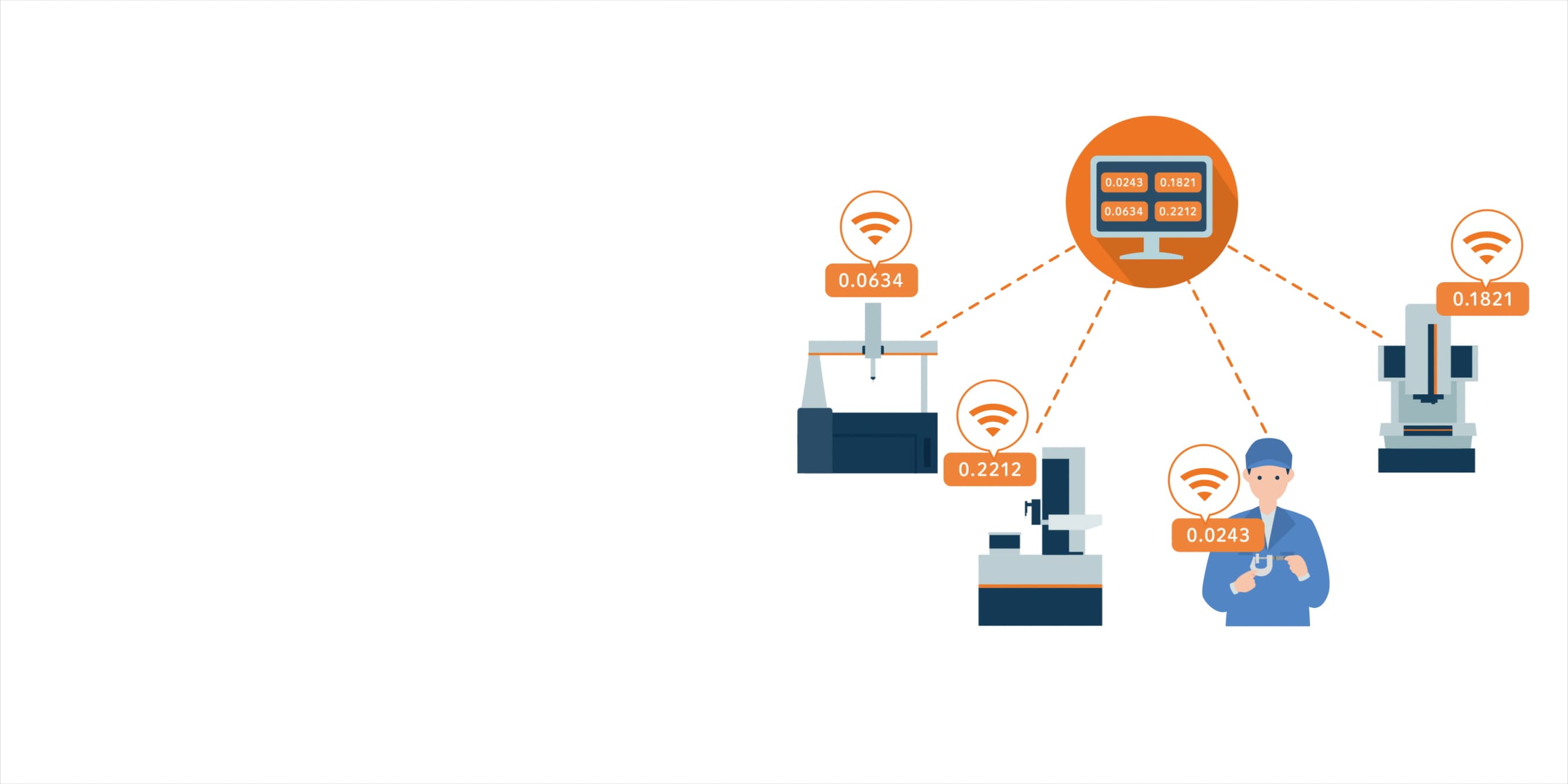

お客様のニーズに応える5,500種類以上の商品で、ものづくりの現場に革新を

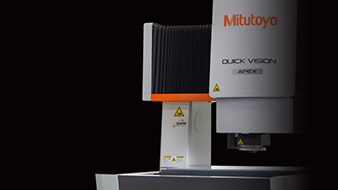

計測機器

三次元測定機 / 画像測定機 / 形状測定機 / 硬さ試験機 / 光学機器 / X線CTシステム

センサ・装置組込ユニット

接触センサ / 非接触センサ / スケールユニット / 光学機器 / マイクロメータヘッド

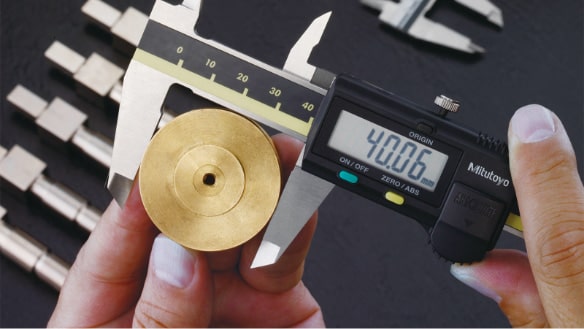

測定工具

マイクロメータ / ノギス / ハイトゲージ / デプスゲージ / 内径測定機 / ダイヤルゲージ・テストインジケータ

すべてのお客様が、世界品質のミツトヨ商品を安心してお使いいただけるように

導入支援から定期的な検査・校正、万一の故障修理、教育支援など、お客様がミツトヨ商品を本来の性能で安心して使い続けられるよう、国内・海外ともに充実の体制でサポートします。

創業時のベンチャー精神を土台に、明日へチャレンジする人を求めます

これから入社する皆さんは、100年企業を目指す当社を牽引していく人材。ミツトヨは、変化に対応するのではなく、時代の変化を読み、自ら変化を作り出せる人を求めています。