- Home

- News

Press Release

November 6, 2019

Mitutoyo launches its Rockwell Hardness Testing Machine

HR-600 Series enabling measurement of large workpieces mounted as is.

|

|

|

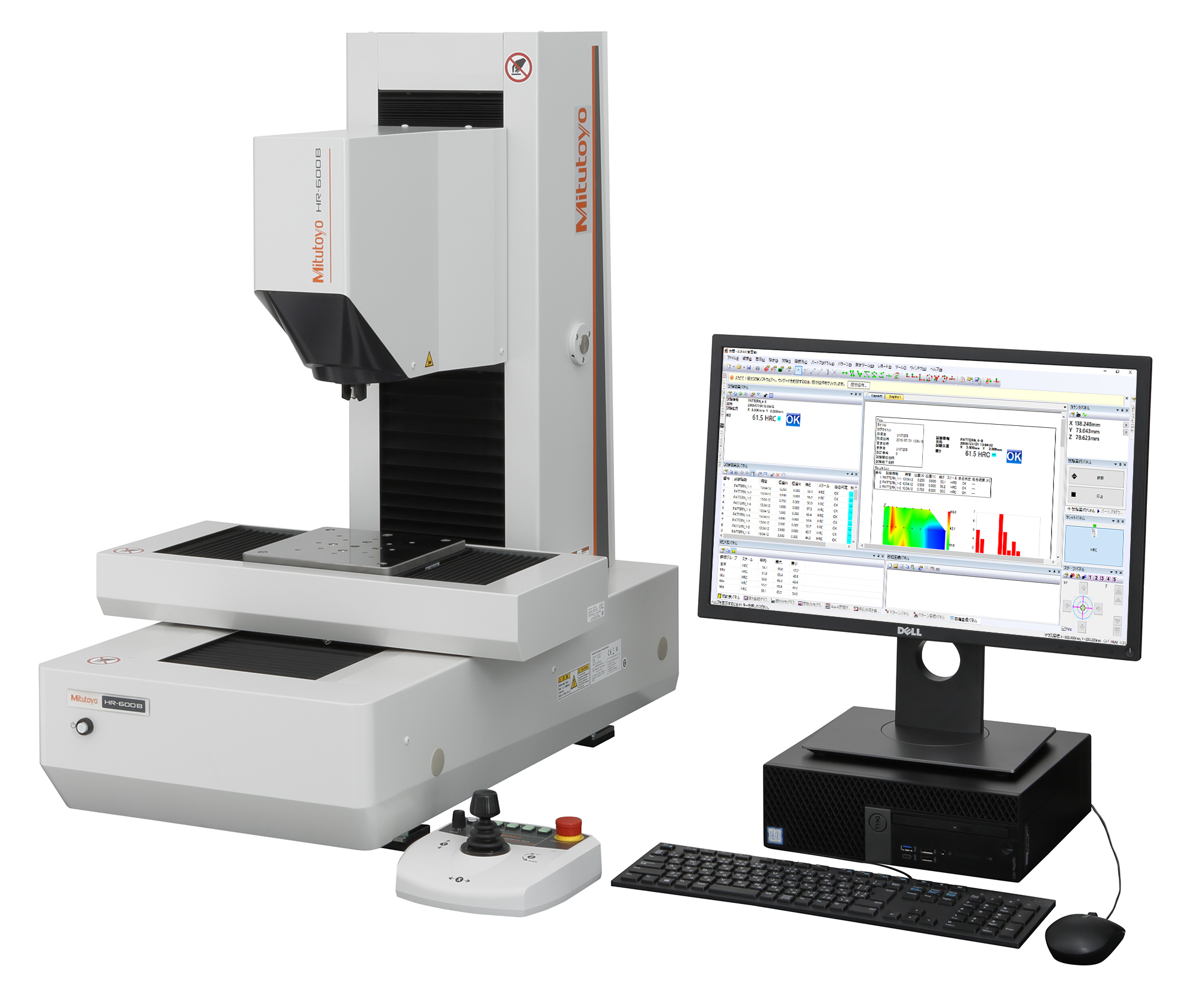

HR-620B (PC TYPE) |

Able to test large, heavy workpieces X-axis |

Mitutoyo Corporation (headquarters: Takatsu Ward, Kawasaki City, Japan; President: Yoshiaki Numata) has developed and launched its Rockwell Hardness Testing Machine HR-600 Series.

HR-600 is a Rockwell hardness testing machine able to test large, heavy workpieces mounted on the table as is, without disassembly, such as cylinder heads and cylinder blocks, that could not be handled with conventional devices. The series revolutionizes conventional testing machines, being the first Mitutoyo model with a moving head, moving at a speed of 10 mm/s within a 210 mm range. The indentation depth measurement mechanism uses a contactor to enhance testing accuracy. In addition, installation of a motorized X-axis stage device that can combine with part programs enables automatic multi-point Rockwell testing of multiple points and items. Furthermore, the addition of FORMEio V4 to AVPAK V3 in the PC TYPE model and connection with transfer system and signal towers enable assembly of a fully automatic hardness testing system that can also transport objects.

In addition to being able to perform both Rockwell and Brinell hardness testing on a single machine, it can also test the hardness of plastics. Furthermore, it can perform indentation Brinell and Vickers hardness testing, which do not require image measurement.

The display screen offers five display options so that the user can choose according to the results they need to see, to view test results on the spot. Furthermore, the touch-screen delivers excellent usability. It also offers many features useful for measurement and analysis such as enabling the user to directly select hardness scale and statistical analysis features that can help analyze multiple test results. The enhanced usability can streamline workflow, including the reduction of measurement and analysis time.

The unit design realizes both enhanced on-site usability and functional beauty, adopting bold coloring representing innovation and creativity appropriate for precision measuring instrument for the IoT era.

Mitutoyo contributes to society through precision measurement for the ever-evolving future of manufacturing.

[Main specifications]

| Order No. | metric | 810-510-11 | 810-511-11 | 810-520-11 | 810-521-11 | 810-525-11 | 810-526-11 |

| Inch/mm | 810-510-13 | 810-511-13 | 810-520-13 | 810-521-13 | |||

| Model | HR-610A | HR-620A | HR-620B | ||||

| Indenter type*1 | 1/16 in Steel ball | 1/16 in Tungsten carbide ball |

1/16 in Steel ball |

1/16 in Tungsten carbide ball |

|||

| Hardness testing methods |

Rockwell | JIS B 7726, ISO 6508, ASTM E18*2 | |||||

| Brinell*3 | JIS B 7724, ISO 6506, ASTM E10 | ||||||

| Plastic | - | ISO 2039-1 | |||||

| JIS K 7202, ISO 2039-2, ASTM D785 | |||||||

| Indentation Brinell hardness |

VDI/VDE 2616 | ||||||

| Indentation Vickers hardness |

- | VDI/VDE 2616 | |||||

| Initial test force N (kgf) |

Rockwell | 29.42 (3) 98.07 (10) | |||||

| Plastic | - | 9.807 (1) | |||||

| 98.07 (10) | |||||||

| Indentation Brinell hardness |

98.07 (10) 490.3 (50) | ||||||

| Indentation Vickers hardness |

- | 9.807 (1) | |||||

| Test force N (kgf) |

Rockwell | 147.1 (15) 294.2 (30) 441.3 (45) 588.4 (60) 980.7 (100) 1471 (150) | |||||

| Brinell*3 | 49.03 (5) - 1839 (187.5) | 9.807 (1) - 2452 (250) | |||||

| Plastic | - |

49.03 (5) 132.4 (13.5) 358.0 (36.5) 962.1 (98.1) | |||||

| 588.4 (60) 980.7(100) 1471 (150) | |||||||

| Indentation Brinell hardness |

612.9 (62.5) 1839 (187.5) 2452 (250) | ||||||

| Indentation Vickers hardness |

- | 294.2 (30) 490.4 (50) | |||||

| Power supply | AC100 V, 120 V, 220 V, 240 V (Selectable) | ||||||

| External dimension |

Main unit (W×D×H) |

350×681×935mm | 428×837×935mm | ||||

| Display | 191(W)×147(D)×71(H)mm | ||||||

| Mass | 176 kg | 181 kg | 205 kg | ||||

*1: Supplied as standard.

*2: Please contact us for information on ASTM standards.

*3: For Brinell hardness testing, an indenter (option) and a measurement microscope are required.

[Main Features]

| • | Unlike conventional testing devices, large workpieces weighing up to 100 kg can be mounted on the table as is to conduct hardness testing. |

| • | An indentation depth measuring mechanism that uses a contactor. Enables more precise Rockwell hardness testing to measure indentation depth from the workpiece surface. |

| • | Installation of a motorized X-axis stage device can combine with part programs to enable automatic multi-point Rockwell testing of multiple points and items. |

| • | In addition to being able to perform both Rockwell and Brinell hardness testing of metals, it can also test the hardness of plastics. Furthermore, it can perform indentation Brinell and Vickers hardness testing, which do not require image measurement. |

| • | Connecting the PC TYPE model with transfer system and signal towers enables full automation of Rockwell hardness testing. |