- Home

- News

Press Release

November 28, 2016

In-line inspection system designed for the automobile industry to achieve

"100% (all parts) x 100% (all features)" inspection

"Mapvision Quality Gate series" to be released

Mitutoyo Corporation and Mapvision Ltd. (Helsinki, Finland) have announced their intention to enter into a strategic alliance with the aim of expanding and adding value to their in-line measurement and product line-up. To facilitate this objective, Mitutoyo Corporation has acquired approximately 10% of Mapvisions's issued shares with an investment of newly subscribed shares.

Mitutoyo will be able to sell and provide services for Mapvision’s in-line inspection system "Quality Gate" by using Mitutoyo’s extensive global sales and support network.

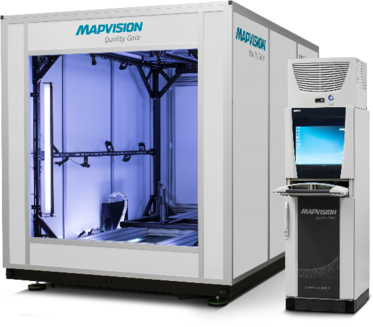

The "Quality Gate" system is an innovative, high speed, in-line inspection system with "100% (all parts) x100% (all features)" inspection capability. Complex welded assemblies like cross car beams, sub-frames and axles can be measured very fast (typically within 30 seconds), which greatly contributes to automation efficiency and reduction of downtime for smart factories.

Mitutoyo will exhibit the system in Japan for the first time at JIMTOF2016, the 28th Japanese International Machine Tool Fair, on November 17 (Thu.) through 22 (Tue.) in 2016, and will be located at Booth No. W3022, West Hall 3, at Tokyo Big Sight.

Mitutoyo makes a social contribution by providing precision measurement for the continual evolution of manufacturing.

[Key Features]

■Unique multi-camera system

Software measurement is enabled by applying machine vision using multiple cameras. High reliability, high factory utilization and the robustness needed for production lines are inherent to the system.

■Unique "100% (all parts) x 100% (all features)" inspection

With the fastest inspection speed in the industry, all features on all parts are inspected. Each inspection is carried out in only 10 to 30 seconds, typically.

■All-in-one (In-line inspection)

Dimensional inspection that depends on gauges and coordinate measuring machines, together with an appearance check, is always subject to risk of human error but inspection can be completed by this single system while avoiding any such risk.

■Ideal in-line design

There is no mechanical issue or constraint caused by the use of robots and probes. The simple design and structure of components deliver high reliability and easy maintenance.

■Realization of a smart factory

Process capability can be fully visualized, which allows you to achieve unprecedented improvement. An optimized production line, reduction of downtime, full automation, reduction of waste products, reduction of defect cost to zero, and any other profitable effect can be achieved.

[Key Specifications]

| Specifications | ||

| Applicable parts | For QualityGate4200 | car beams, sub-frames, axles, etc. |

| For QualityGate6200 | Body, chassis, ladder frame, etc. | |

| Inspection for | Dimensions | Point coordinates, distance, angle, edge, corner, surface, etc. |

| Confirming presence/absence | Nuts, clips, screw thread, etc. | |

| Performance | Repeatability | 0.02mm |

| Correlation to a coordinate measuring machine | 0.1mm | |

| Measurement time | 10~30 seconds | |