- Home

- News

Press Release

November 30, 2016

Increased durability, sensitivity, and visibility

Improved Dial Test Indicators to be released

Mitutoyo Corporation (Headquarters: Takatsu-ku, Kawasaki City, Kanagawa Prefecture; President: Toru Nakagawa) has remodeled its lever type dial indicators (commonly known as "Dial Test Indicators"). This product will be introduced in January 2017 and exhibited at JIMTOF2016, the 28th Japanese International Machine Tool Fair, held at Tokyo Big Sight (Booth No.W3022, West Hall 3) on November 17 (Thu.) through 22 (Tue.) 2016.

The Dial Test Indicators were previously remodeled in 1993 to improve the auto clutch mechanism and modify the structure so that the pointer turns clockwise regardless of which direction (upward or downward) the contact point moves. In 1994, to make it easier for users to read the pointer from an oblique position, we released the "Horizontal (20° tilted face) Dial Test Indicator" whose dial is tilted to make it easier to read in many situations. In 2007, we released the "Dial Test Indicator with a ruby contact point," which is completely non-conductive and so is suitable for use on electrical discharge machines, and is superior in wear resistance.

In this model upgrade we have increased durability, sensitivity and visibility while providing longer contact point for models having a graduation of 0.001mm and 0.002mm, together with introducing a more convenient method of stem attachment.

Some of our customers say the Dial Test Indicators become less sensitive or less responsible when they have been used for a long time. The problem is often caused by loosening of the contact point bearing screw. When this happens a gap is created in the thrust direction and a small amount of play is also created in the measurement direction, which results in decreased sensitivity. In the remodeled Dial Test Indicators the structure holding the contact point has been redesigned so that this screw is now contained inside to prevent it from loosening even after long use, prevent sensitivity degradation, and improve durability.

To increase visibility, a flat-faced crystal and an anti-reflection coating are used. This improvement helps prevent surface defects and also reduces light reflection even in an environment where fluorescent tube or LED lighting is used, making it easier to read the scale.

There was a usability-related request from many customers to make the contact point longer. In this model change, the contact point for models with a graduation of 0.001mm is longer by about 2mm (12.8=>14.7mm) and for those with a graduation of 0.002mm by about 4mm (14.7=>18.7mm) to improve user friendliness.

Although conventional models were provided with φ6 threaded stems as standard, they have been replaced with stems with dovetails since this model change. The body of the Dial Test Indicator has three dovetails, which allows you to install it in the position most suitable for your application and so greatly improves operating convenience.

Complying with the newly revised JIS B 7533:2015 standard, Dial Test Indicators are also tested according to our own inspection standards defined to ensure accuracy at 6 specified positions. (Only the lateral position is inspected at the time of shipment.)

Mitutoyo makes a social contribution by providing precision measurement for the continual evolution of manufacturing.

[Key Features]

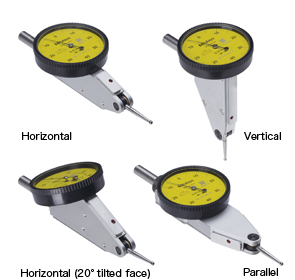

• In addition to the standard Horizontal type, Vertical, Horizontal (20° tilted face), and Parallel types are provided to suit your purpose.

• The crystal is flat and coated so as to reduce reflection from fluorescent tube or LED lighting.

• Its integrated structure of the outer frame and the crystal prevents cutting oil or coolant from penetrating the front surface.

• For models with a graduation of 0.001mm and 0.002mm, the contact point is longer by 2~4mm which makes them easier to use.

• Those indicators equipped with a ruby contact point are completely non-conductive and can be safely used on electrical discharge machines.

• A φ6 stem that attaches directly to a dovetail on the indicator body is provided as standard, allowing installation using any of the dovetail positions on the indicator body.

• Manufacturing and inspections are conducted in compliance with JIS B 7533:2015. (Inspection position: lateral.)

• An inspection certificate is provided as standard. (This certificate cannot be used to obtain a certificate of calibration as it is undated.)

[Specifications for five main models]

| Code No. | 513-401-10H | 513-404-10H | 513-405-10H | 513-424-10H | 513-415-10H |

| Range | 0.14mm | 0.8mm | 0.2mm | 0.5mm | 1.0mm |

| Graduation | 0.001mm | 0.01mm | 0.002mm | 0.01mm | 0.01mm |

| Contact point length | 14.7mm | 20.9mm | 18.7mm | 22.3mm | 44.5mm |

| Measuring range accuracy | 4μm | 9μm | 4μm | 6μm | 10μm |

| 10-scale-division accuracy | 2μm | 5μm | 2μm | 5μm | 5μm |

| Hysteresis | 3μm | 4μm | 3μm | 4μm | 5μm |

| Repeatability | 1μm | 3μm | 1μm | 3μm | 3μm |