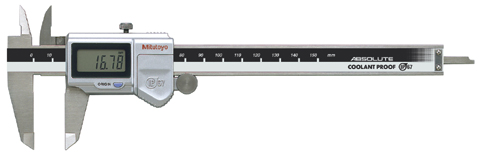

Mitutoyo Corporation (head office: Takatsu-ku, Kawasaki City, Kanagawa Prefecture; president: Kazusaku Tezuka) announced that it has developed and commercialized the CD67-PS series of ABS coolant-proof digital calipers that has achieved IP67 under the International Protection (IP) level*. The new series is considered to be the top-of-the-line model in terms of dustproof and waterproof capabilities which can be used without anxiety even at manufacturing plants, a severe environment usually exposed to a large quantity of coolant. The launch of the new product is scheduled for January 21.

Recent years have the rapid spread of digital measuring tools. Nevertheless, operators at manufacturing plantsムa severe environment where tools are usually exposed to water, oil, and soilムhave been hesitant to use such digital tools because of problems concerning dustproof and waterproof capabilities. In October 2000, Mitutoyo launched the CD-G series of digital vernier calipers with the IP65 protection level, which is revolutionary enough to overturn the established theory within the industry. In October 2003, it also unveiled the CD-P series whose protection level was raised to IP66 to withstand much severer working conditions. These new products have had a great impact on the marketplace.

And now, the company has developed and commercialized the CD67-PS series of ABS coolant-proof calipers having achieved the IP67 protection level considered the ultimate in terms of dustproof and waterproof capabilities. As the world's leading manufacturer of precision measuring machinery, Mitutoyo has incorporated all of its resources for product development and production technology to create this highly-advanced digital vernier caliper.

Using the new product, which is equipped with an absolute encoder having the "absolute origin" regarded as the main feature of Mitutoyo's digital vernier calipers, there is no need to worry about the process of setting the origin point, just like the mechanical type with graduation. What's more, the product can be used for a long time without having to replace the battery. This successfully meets the long-standing demand of customers for the conventional mechanical type model to be replaced by a digital type one with highly value added even at manufacturing plants. Another advantage is the significant improvement in the sliding performance of the vernier caliper's slider section, which is the key element that determines the feel of caliper operation. Thus, Mitutoyo is to market a state-of-the-art digital vernier caliper.

Mitutoyo's ABS coolant-proof calipers undergo general tests according to procedures* specified by the IP standard. Before being shipped out from the factory, all of the products also undergo air-leak tests to guarantee that they are waterproof. In addition, they undergo stringent performance evaluation to guarantee the total quality by means of testing (1) the temperature environment to validate the reliability under severe temperature environments, (2) the working environment to test long-time continuous operations, and (3) the electrical section to check the functions of the switch and other electrical components.

|